Pulsed Eddy Current

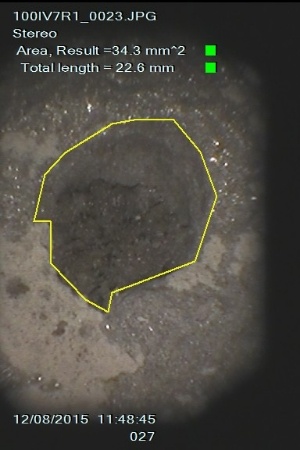

Pulsed Eddy Current (PEC) and other advanced eddy current inspection techniques are ideal tools for detecting corrosion under insulation (CUI) and fireproofing (CUF).

Overview

Advanced eddy current inspection technology can help detect hidden corrosion before it becomes a potentially expensive and hazardous problem. Inspectahire utilises Pulsed Eddy Current (PEC) and PEC Array (PECA) inspection services for tanks, spheres, piping systems, and other assets.

We have undertaken the inspection of over 600 wells in the North Sea to check on their integrity - the benefit of PEC being that we don't need to do any surface preparation or remove marine growth.

Inspection services made for your industry

Oil & Gas

Having worked for three decades in the Oil & Gas industry, both in the North Sea and Worldwide, we have built up a strong expertise in this sector. Due to the shape, environment or size of assets it can make you wonder how you should go about safely ensuring that they are: free from corrosion, operating effectively and not leaking.

Power Generation

Often the shape or size of your asset can make you wonder how you should go about ensuring that it is: safe, free from corrosion, operating effectively or not leaking. All the while you need to ensure that downtime is kept to a minimum as time is money.

Manufacturing Sites

Keeping production facilities operating efficiently is a fundamental driver for all owners of such sites, and our range of NDE services such as Thermography and Gas emission surveys, mean that plants can be monitored whilst remaining in operation. When outages are planned, our teams can then support invasive investigations.

Equipment for the solution

If you are looking to purchase the latest, high-quality inspection equipment then take a look below at some of our featured products below, or explore our full range for more.

Check out our latest projects

Inspectahire has worked on a diverse range of projects across the world. Learn more about what we do and our equipment!