Visual Inspections

Inspectahire covers all aspects of weld and fabrication inspection using Visual Inspection for the manufacturing, construction and commercial industries all over the Australia.

Overview

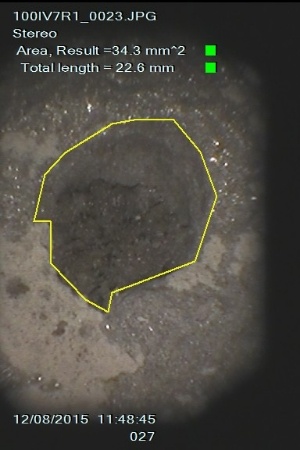

Visual inspection is a popular quality inspection method and is one of the most common Non-Destructive Testing (NDT) methods. It involves a visual testing of welds and components. It is capable of detecting surface-breaking defects, as many welding flaws are on the surface, these can easily be detected via this weld inspection procedure.

Inspectahire employs all levels of CSWIP and PCN Inspectors. Visual inspection is the monitoring of specific parameters by visual and optical assessments of test objects and surfaces using the visible portion of the electromagnetic spectrum.

Visual In-Service Inspection

Visual inspection is a vital part of an in-service inspection, which may or may not be backed up by other NDT methods. The examinations made are for fatigue cracks creep failure, corrosion, erosion, abrasion, mechanical damage, wear and tear, distortion, and poor workmanship.

Inspection services made for your industry

Oil and Gas

Having worked for three decades in the Oil & Gas industry, both in the North Sea and Worldwide, we have built up a strong expertise in this sector. Due to the shape, environment or size of assets it can make you wonder how you should go about safely ensuring that they are: free from corrosion, operating effectively and not leaking.

Power Generation

Often the shape or size of your asset can make you wonder how you should go about ensuring that it is: safe, free from corrosion, operating effectively or not leaking. All the while you need to ensure that downtime is kept to a minimum as time is money.

Civil Engineering

Ensuring your assets are structurally sound and well-maintained is important as the implications can be far-reaching. However, at times you may wonder how you should go about doing that due to their size, shape, environment or location. Since we were established in 1981, we have gained significant international multi-industry experience carrying out inspections on office buildings, piles, housing, shopping centres and and bridges.

Pharmaceuticals

Every industry has risks, but the level and type of these varies from industry to industry. Often the solution to overcome the risk and problem is the same irrespective of the industry. We have gained significant international multi-industry experience since we were established in 1981.

Renewables

As people and businesses become more environmentally aware and want to reduce their carbon footprint, the switch to renewable energy gathers pace. To meet this demand the number and scale of wind farms are increasing, and so too is the requirement to ensure they are operating effectively.

Food and Drink

Risks appear in every industry, but the type, scale and impact vary. Identifying the problem and solving it quickly is important. Often you wonder due to the size, shape, environment or location of your asset, how you should safely inspect it for leaks and structural integrity. Using skills developed across three decades of international multi-industry work, we are able to provide creative inspection solutions using the latest technology.

Equipment for the solution

If you are looking to purchase the latest, high-quality visual inspection equipment then take a look at some of our featured products below, or explore our full range for more.

Check out our latest projects

Inspectahire has worked on a diverse range of projects across the world. Learn more about what we do and our products!